Great Lakes Barcode is a leading provider of industrial scanning and machine vision solutions. With over 40 years of experience, we are committed to providing our customers with the highest quality products and services.

We will share information and success stories about how you can use Vision Systems and Barcode Scanners to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

There’s no doubt about it. The U.S. manufacturing sector has faced and overcome huge challenges over the past few years. While you admire their resourcefulness, you want to help your manufacturing partners succeed.

With the beginning of a new year, you may wonder if the pain points in the manufacturing industry have retreated or at least diminished. Unfortunately, American industrial companies still have more than enough headaches ahead.

Address these five major manufacturing pain points for 2023 through your website, emails, meetings, and other touch points. These simple steps can help you cement your relationship with your current clients and find new clients most in need of your products and services.

As the Federal Reserve fights to keep inflation down, the result is This change will affect not only your company’s ability to purchase materials but also your customers’ ability to purchase your product. For your prospects in manufacturing, look at putting together as favorable a financing deal as you can. You may also offer options such as leasing.

If you provide financial services, you may find heightened demand in the U.S. manufacturing sector. Now’s the time to reach out to CFO’s and business owners in industries most affected by high prices. Additionally, you can help you clients by referring them to an industrial marketplace like IndustryNet, with rising interest rates. where they can source and quote multiple companies for the best price.

While the chilling effects of COVID are reduced, if your company employs machinists, you know how hard it still is to find skilled workers. Job openings in manufacturing are at historic levels. Many master craftsmen chose to retire or are considering doing so. When you’re competing with behemoths like Amazon, even finding warehouse workers can be a struggle. If you can’t make and adequately store your product, you can’t sell it. Consult with HR to strategize the deployment of limited personnel to produce sufficient merchandise. Then concentrate on selling what’s easiest to turn out.

Additionally, if your company provides staffing, training, or workforce development services, now is the time to take a proactive approach and reach out to manufacturing companies in need of labor solutions. IndustrySelect can help you reach the decision-makers most relevant to your type of business. Types of executive decision-makers in IndustrySelect’s database of nearly 400,000 manufacturers include those in Human Resources, Health & Safety, Research & Development, and more,

Although supply chain disruptions have largely eased as we move into 2023, the challenge remains.

Decades ago, many manufacturers decided to outsource parts and electronics manufacturing. At the time, Asia could make small parts more cheaply than American manufacturers. Poor quality control and raising wages overseas have since made outsourcing less inviting. Increased shipping times also make it hard for manufacturers to plan accurate production schedules. And, of course, COVID was the ultimate icing on the supply chain disruption cake.

If you’d hoped that as concern for COVID recedes, supply chains would lose their kinks, you’re in for a disappointment. The pandemic was not the only event disrupting the flow of raw materials and components.

Manufacturing pain points as supply chain disruptions lead to materials shortages for many small- to medium-sized manufacturers. Although the severe shortages of 2021-2022 have begun to ease, shortages are still an issue for many industrial companies. Even though it is not “lean,” manufacturers should consider strategic stockpiles of vital parts. Just-in-time ordering frees up warehouse space. However, it can also leave your manufacturers without the parts they need when they need them.

Help your companies take a close look at the parts that keep their production lines humming. It is worth the cost of extra storage space to keep major parts on hand. If your company provides products and services that are in short supply, now is the time to reach out to more manufacturers. See IndustrySelect’s intent data resources to discover what products and services are trending right now.

Industry 4.0 promised to ease some manufacturing pain points. Unfortunately, the research and investments required have turned into issues in and of themselves. Manufacturers still don’t have a full picture of what smart automation actually does, with the industry adopting solutions without a unified vision.

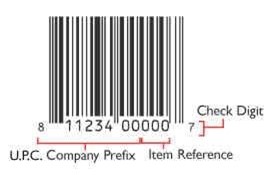

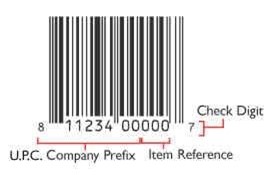

On the plus side, factory and warehouse automation do ease the labor shortage. Wireless networks make some of this automation possible. RFID chips track parts throughout the warehouse until the finished product ships. Wireless also gives floor managers a clear overview of every production point.

So, small- to medium-sized companies can see the benefits of automation but aren’t yet positioned to take full advantage of them. If your company provides automation solutions, now is the time to step up your prescriptive selling efforts and home in on automation solutions for your clients.

• The U.S./China trade war

• Natural disasters, including severe flooding, hurricanes, and droughts

• Logistics complications, such as national railway strikes

So how are sales and marketing professionals to navigate the bumpy road ahead?

First, if you are in manufacturing, keep fully abreast of any hitches with your company’s production. If you’re not seeing products coming off the line, you’ll know better than to make promises you can’t keep. However, if the merchandise is warehoused and ready to be shipped, ensure that you and your team press for every deal you can make. Slowdowns may occur at any time.

The Reshoring Initiative offers resources to manufacturers who want to bring their work home to America. A shorter supply chain carries less risk of disruption. If your company provides products and services that are in short supply, now is the time to reach out to more manufacturers. See IndustrySelect’s intent data resources to discover what products and services are trending right now.

If you are not in manufacturing, but sell to manufacturers, familiarizing yourself with manufacturing terminology can help you speak your client’s language. See this informative glossary of 80 manufacturing-related terms and definitions.

If you have questions about us or the products, we are available to answer those questions through email or phone.

We have experienced technicians on standby to answer all your questions and find you the part you need.

Contact us: Click here

Give us a call: 763-276-3446

or

E-mail us directly: Sales@GreatLakesBarcode.com